MB-320 Online Practice Questions and Answers

A company is implementing Dynamics 365 Supply Chain Management in their manufacturing environment. The manufacturing process uses formulas to direct material consumption on the batch orders.

During production some items in the formula must be consumed automatically from the production area, while some must be picked with their actual consumption reported on a pick list.

You need to determine which setup method is used for formula lines to allow for the desired mixed method picking processes.

What are two possible ways to achieve this goal? Each correct answer presents a complete solution. NOTE: Each correct selection is worth one point.

A. Leave the flushing principle blank on formula lines and set resource consumption to direct flushing principle of materials based on consumption method for the line.

B. Leave the flushing principle blank on formula lines and set the default start value to Always for Automatic Bill of Material Consumption.

C. Leave the flushing principle blank on formula lines and set default flushing principle on the items based on consumption method for the item.

D. Set the flushing principle on each formula line based on consumption method for the line.

Note: This question is part of a series of questions that present the same scenario. Each question in the series contains a unique solution that might meet the stated goals. Some questions sets might have more than one correct solutions,

while others might not have a correct solution.

After you answer a question in this section, you will NOT be able to return to it. As a result, these questions will not appear in the review screen.

A company implements Dynamics 365 Supply Chain Management for their Lean manufacturing environment.

There has been an engineering change to a fixed quantity product that is in production. This change will add an additional processing step as the second step. The existing version must be phased out and replaced by the new version.

You need to ensure that the engineering change takes affect at the end of the month.

Solution:

1.) Edit the existing step number two activity to be the new engineering process 2.) Edit the existing production flow. Set the expiration date due to the end of the month 3.) Edit the existing Kanban rule. Set the expiration date to the end of the month 4.) Activate the production flow

Does the solution meet the goal?

A. Yes

B. No

A company configures master planning to order large and expensive aluminum sheets that are only available at certain times of the year.

The warehouse manager reports that replenishment levels are too high, causing inventory value to be over budget. In addition, the aluminum sheets take up too much space on the shop floor.

You need to configure the appropriate replenishment method.

Which coverage dimension should you use?

A. Min/Max

B. Per period

C. Per requirement

D. Manual

SIMULATION

You are a functional consultant for Contoso Entertainment System USA (USMF).

The factory of USMF has a shift that runs during the hours of 06:00 to 14:00 from Monday to Friday.

You plan to create a calendar that will use the shift.

You need to create the factory shift in the system.

To complete this task, sign in to Dynamics 365 portal.

SIMULATION

You are a functional consultant for Contoso Entertainment System USA (USMF).

USMF plans to categorize a new night shift in its factory.

You need to create a new cost category named NightShift for the night shift.

To complete this task, sign in to Dynamics 365 portal.

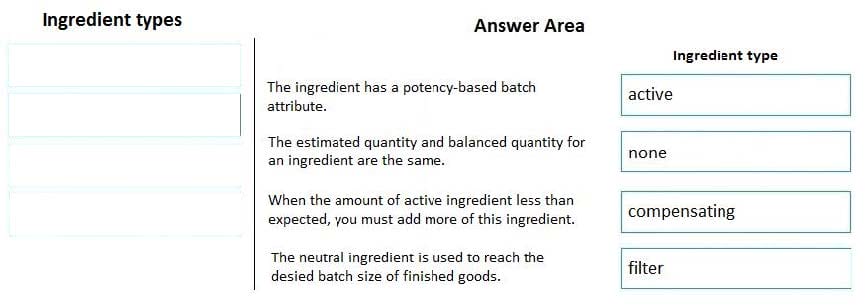

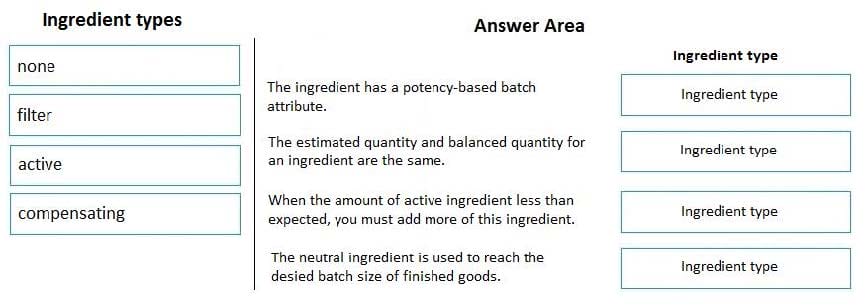

A company uses Process manufacturing.

You need to review formulas and how the different ingredient types impact the batch balancing process.

Which ingredient types should you use? To answer, drag the appropriate ingredient types to the correct scenarios. Each ingredient may be used once, more than once, or not at all. You may need to drag the split bar between panes or scroll

to view content.

NOTE: Each correct selection is worth one point.

Select and Place:

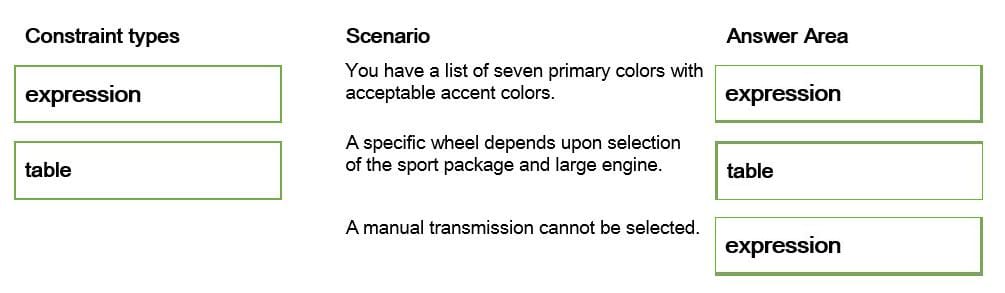

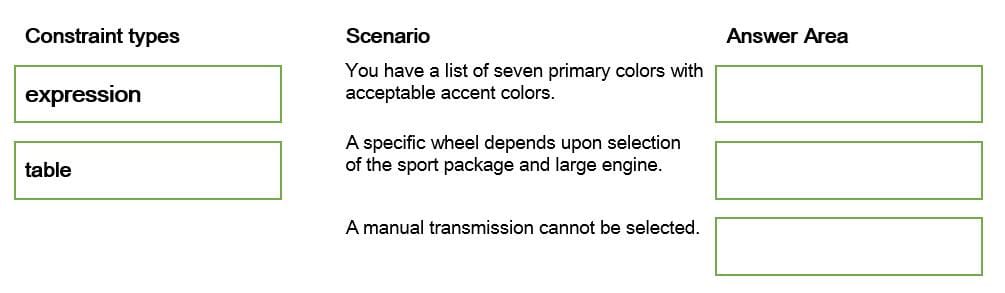

You are the product definition manager for a car manufacturing company. You set up and maintain the production configuration models used at the company.

You must build a new configuration model and include constraints in the model.

You need to determine which constraint type to use for each scenario.

Which constraint type should you use? To answer, drag the appropriate constraint types to the correct scenarios. Each constraint type may be used once, more than once, or not at all. You may need to drag the split bar between panes or

scroll to view content.

NOTE: Each correct selection is worth one point.

Select and Place:

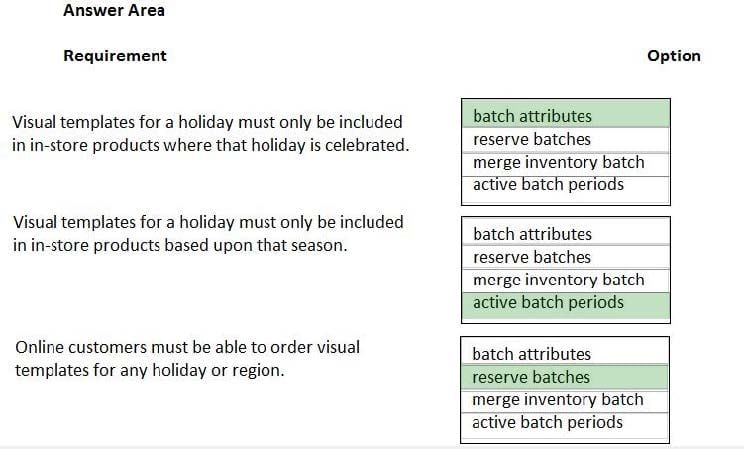

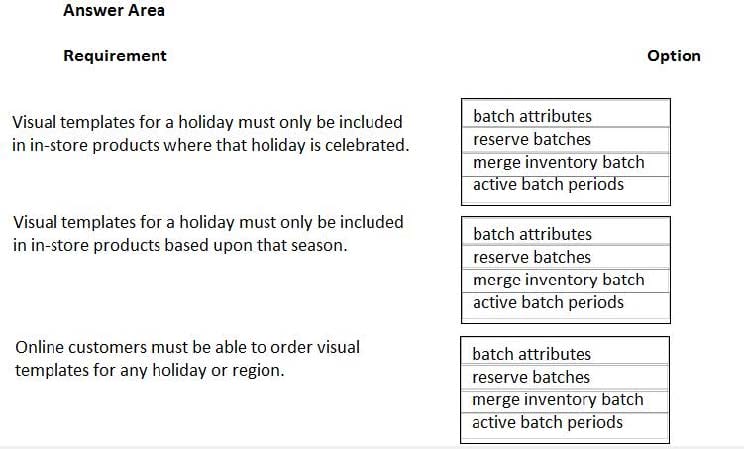

HOTSPOT

A company produces light projection toys for holiday decorations. The company plans to implement Lean manufacturing processes.

Production master data must meet the following requirements:

1.

Visual templates for a holiday must only be included for in-store products where that holiday is celebrated

2.

Visual templates for a holiday must only be included for in-store products based upon that season

3.

Online customers must be able to order visual templates for any holiday or region.

You need to implement production master data.

What should you configure? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

Hot Area:

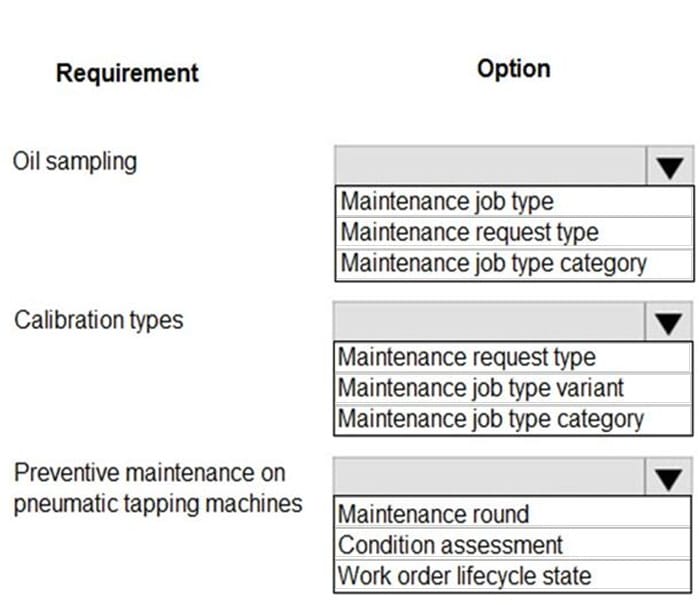

HOTSPOT

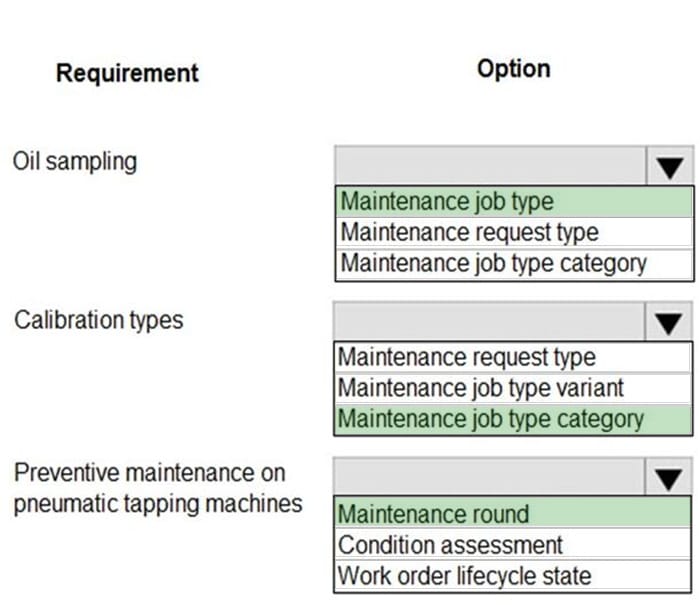

A company uses Dynamics 365 Supply Chain Management.

The company plans to use the Asset management module to maintain its installed base of milling machine fixtures.

The module must be configured to handle the following requirements:

An oil sampling must be taken from each machine at regular intervals.

All calibration types (tooling, instrumentation, and tolerances) that share a required performance skillset must be managed together.

The company is unable to perform in-house preventive maintenance skills on the pneumatic tapping machines. Therefore, the company hires outside services for it.

All maintenance must be scheduled at the same time for efficiency and cost savings.

You need to configure the system.

Which option should you configure? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

Hot Area:

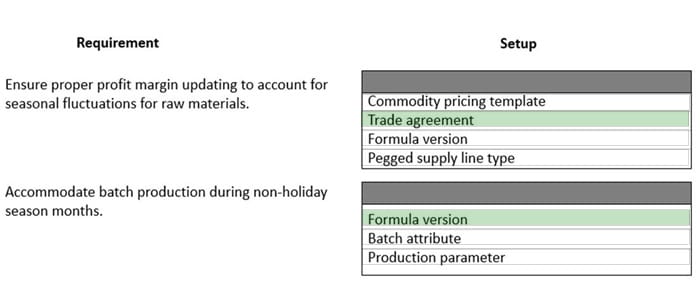

HOTSPOT

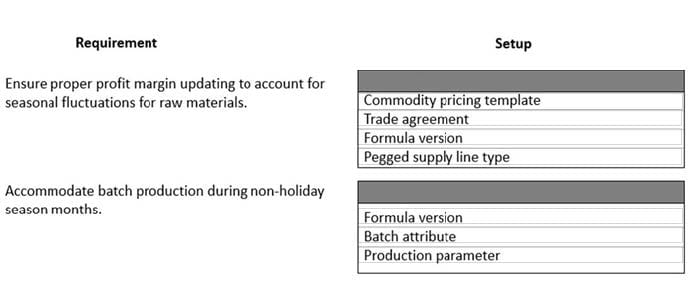

You need to configure the system to meet the requirements.

What should you use? To answer, select the appropriate options in the answer area.

NOTE: Each correct selection is worth one point.

Hot Area: